The moving part which does not use reduction gears can be built.īecause the Ultrasonic Motor uses neither the coil nor the magnet, it is not affected about operationĪnd an ultrasonic motor does not generate magnetism during rotation.For this reason, the stable operation Moreover, because it has high holding power at the time of un-applying an electric current,

#Piezo motor series

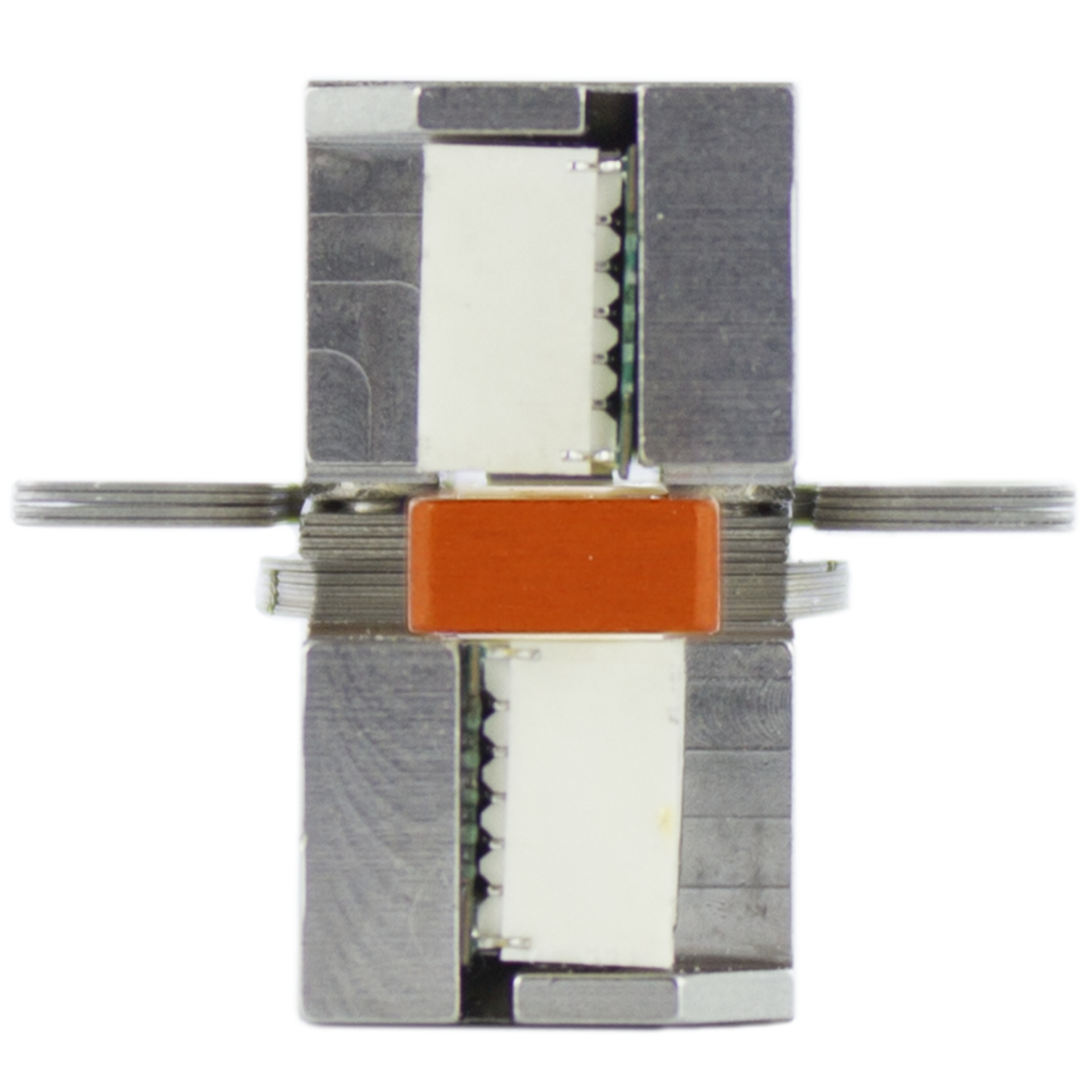

SHINSEI CORPORATION's Ultrasonic Motor:USR series is small size, a low speed, and high torque,Īnd is excellent in a response and silence. Image of the pressure between Rotor and Stator So, When a traveling wave progresses in the clockwise direction (CW) on the circumference of a stator, each peak of the traveling wave in contact with a rotor carries out elliptical movement in the counterclockwise direction (CCW).Īnd the rotor in contact with the peak of the wave rotates in the counterclockwise direction (CCW).īy controlling the speed and direction of this traveling wave, control of an Ultrasonic Motor is possible. And a rotor rotates in the direction contrary to a traveling wave under the influence. The direction of movement of this ellipse is a direction contrary to the direction which a traveling wave follows. Here, the stator metal touches the rotor only at each peak of a traveling wave, and each of that peak carries out elliptical movement.Ī rotor rotates in response to the influence of the elliptical movement. The modification amplifies and spreads with stator metal, and generates a traveling wave on the surface of stator metal. If voltage is made to apply to piezo-electric ceramics, the shape of piezo-electric ceramics will be changed or distorted. High pressure is applied between the rotor and the stator.įor this reason, the biggest frictional force at the time of a stop is the holding power of an ultrasonic motor. This wave rotates the rotor which is in contact with the stator. The modification is made to amplify and spread with stator metal, and a traveling wave is generated on the surface of stator metal. If voltage is impressed to piezo-electric ceramics, the form of piezo-electric ceramics will change. The Ultrasonic Motor uses piezo-electric ceramics for the source of a drive. The lineup of USR30 series and USR60 series are the Standard Model Motor assuming the use in general environment and the Non-Magnetic Model Motor assuming the use in high magnetic field environment. The concentration of the technology is USR30 series:diameter 30mm and USR60 series:diameter 60mm.īy the result of continuous improvement, USR30 series and USR60 series are adopted in many companies and academic organizations in the world.Īnd because USR30 series and USR60 series have obtained high evaluation, it is considered as a de-facto standard of Ultrasonic Motor. Then, the SHINSEI CORPORATION's Ultrasonic Motor repeated improvement aiming at improvement in functionality and reliability. The name of an ultrasonic motor was named from the frequency of the voltage that is exceeding people's audible sound region.(Over 20kHz).

Ultrasonic Motor rotates using modification when voltage is applied to piezo-electric ceramics.

The motor is first type of the present Ultrasonic Motor: USR series. The name of the production is USR-60-4-100. In December 25,1986. The completely new motor which uses neither a Coil nor any Magnet for driving force was put on the market from SHINSEI CORPORATION.

0 kommentar(er)

0 kommentar(er)